Catalytic processes at surfaces

Catalytic processes at surfaces

Contact persons: Cristina Africh, A. Baraldi, C. Dri, E. Vesselli, G. Comelli.

|

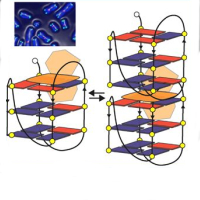

This research line is focused on the determination of the geometric and electronic structure of solid surfaces, with specific interest in the characterization of their chemical activity. A variety of systems, including clean and adsorbate covered transition metal surfaces, ultra-thin oxide films, surface alloys, self-assembled organic monolayers and hetero-architectures, and epitaxial graphene are investigated. The main goal is the understanding of the interaction of adsorbates with surfaces, analyzing the induced structural modifications, the formation of bonds, the changes in the electronic structure at the interface, and the elementary steps involved in surface processes (e.g. atomic and molecular diffusion, segregation, growth, chemical reactions). |

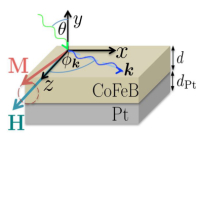

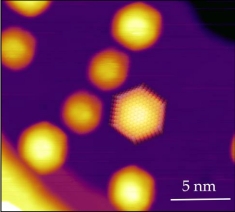

Rh clusters deposited on graphene/Ir(111) [A. Cavallin et al, ACS Nano 6 (2012) 3034-3043] |

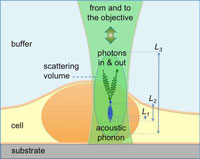

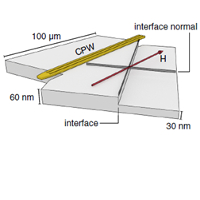

Catalytic systems are investigated by both microscopy and spectroscopy techniques. In particular, Scanning Tunneling Microscopy is used for characterizing at the atomic scale the induced structural modifications. Experiments are performed in a wide range of temperature regimes, from 4K to 900K, to explore different processes and enable complementary approaches. Both temperature- and gas-induced surface kinetics are monitored in- operando with variable frame rates, up to video-rate. At 4K, single molecule vibrational spectroscopy is also applied. X-ray Photoelectron Spectroscopy is often used for chemical characterization before, during and after surface processes; furthermore, Low Energy Electron Diffraction and Thermal Desorption Spectroscopy complement the experiments. In many cases catalytic surface processes are investigated also by synchrotron radiation at Elettra – in particular SuperEsca, Nanospectroscopy and ALOISA beamlines – or at other international facilities. Finally, experimental results are often corroborated with and compared to ab-initio calculations performed by collaborating groups at both local and International institutions. In order to continuously improve the experimental capabilities for the investigation of chemical surface processes, a thorough effort is dedicated to the constantly and progressive update, development, and realization of new instrumentation. In this context, a prototype of an add-on module for fast scanning was developed and implemented in collaboration with the Detectors and Instrumentation Lab of Elettra, and a method for driving a scanning probe microscope at elevated scan frequencies was recently patented. The latter innovation introduces the possibility to investigate a new range of surface process, with an imaging rate exceeding 100 frames/s. To reduce the surface science pressure gap, a novel experimental setup, dedicated to vis-IR sum frequency generation vibrational spectroscopy (SFG) has recently been designed and commissioned. It will allow investigation of surfaces from UHV up to ambient pressure and in liquid, in situ and in operando under (electro)-catalytic conditions.